Market Statistics

| Study Period | 2019 - 2030 |

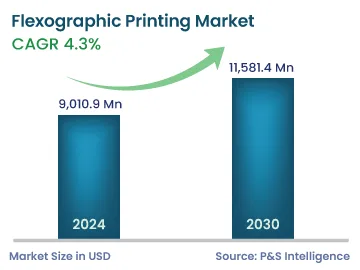

| 2024 Market Size | 9,010.9 Million |

| 2030 Forecast | 11, 581.4 Million |

| Growth Rate(CAGR) | 4.3% |

| Largest Region | Asia-Pacific |

| Fastest Growing Region | North America |

| Nature of the Market | Fragmented |

Report Code: 12804

Get a Comprehensive Overview of the Flexographic Printing Market Report Prepared by P&S Intelligence, Segmented by Application (Corrugated Boxes, Folding Cartons, Flexible Packaging, Labels, Print Media), Method (Inline-Type Press, Central-Impression Press, Stack-Type Press), Offering (Printing Machines, Printing Inks), and Geographic Regions. This Report Provides Insights From 2019 to 2030.

| Study Period | 2019 - 2030 |

| 2024 Market Size | 9,010.9 Million |

| 2030 Forecast | 11, 581.4 Million |

| Growth Rate(CAGR) | 4.3% |

| Largest Region | Asia-Pacific |

| Fastest Growing Region | North America |

| Nature of the Market | Fragmented |

Explore the market potential with our data-driven report

The global flexographic printing market value is estimated at USD 9,010.9 million in 2024 and projected to reach USD 11,581.4 million by 2030, advancing at a CAGR of 4.3% during 2024–2030. This is attributed to the growth in the sale of consumer goods, thereby increasing demand for packaging and printing solutions.

A flexographic printing machine serves as an efficient piece of equipment for medium-to-long-run printing tasks. All consumer products require a label, which is either applied manually or by a machine. Self-adhesive labels also offer valuable assistance in the corporate environment. Flexographic printing allows for the speedy production of medium-to-large self-adhesive label prints, thus making it an excellent choice for businesses.

Print media plays an important role in smoothing communication between consumers and manufacturers, while aiding shipping companies in effectively managing the movement of goods. Flexographic printing is widely used for various packaging materials, such as bags, cartons, labels, and flexible packaging.

Flexography's versatility in printing on diverse substrates extends its applicability to a wide range of products. The food packaging sector is of particular significance due to the capability of this technology to print on non-porous substrates. This feature proves valuable during printing on plastic bags, which are an indispensable packaging item. Flexography, when paired with the right inks, is food-safe and can be effectively used for printing packaging for pharmaceuticals and other medical supplies as well. This method is also suited for utilization on foil wrappings, plastics, sterile bags, and cardboard packaging.

Thus, it is ideal for a range of applications, such as wallpapers, calendars, publishing packaging, laminated tetra packs, books, and food packaging. The substrate being printed on can encompass polymers, paper, textiles, cardboard, and even metalized films, which are polymers coated with a thin layer of metal. The growing need for a multipurpose printing machine that can efficiently handle many substrates and diverse products, mainly for long printing runs on flexible plastic films, is expected to drive the adoption of flexographic printing machines.

Additionally, these systems can operate at high speeds, exhibit applicability across different surfaces, and accommodate both oil-based and water-based inks. They provide numerous benefits for customers using spot colors and finishing processes such as perforating, cold foiling, laminating, and embossing.

Many such machines have been introduced by the global players to ensure optimal performance on a wide range of substrates and for varied production lengths. These presses are distinguished by their rapid setup and changeover processes, automation, and other features that ensure waste reduction, consistent production, and straightforward manufacturing. Further, certain flexographic presses are manufactured with a focus on innovations in shrink sleeves and flexible packaging and models that are also capable of running at speeds of up to 350 meters per minute.

The increasing popularity of flexo–digital hybrid label printing solutions stands out as a pivotal driver in the flexographic printing machine market advance. Such solutions combine the strengths of both digital technologies and flexographic printing. Flexography provides the ability to print with metallics, primers, cold foils, and spot colors, whereas the digital printing technology delivers efficiency by enabling the simultaneous printing of multiple versions and colors in a single pass. Hence, flexo–digital hybrid label printing solutions allow users to enhance throughput and elevate the quality of the printed materials.

For instance, MPS Systems provides the MPS EF SYMJET, a flexo–digital hybrid label printing solution, which combines the automated MPS EF platform with the integrated Domino N610i digital ultraviolet (UV) inkjet label press.

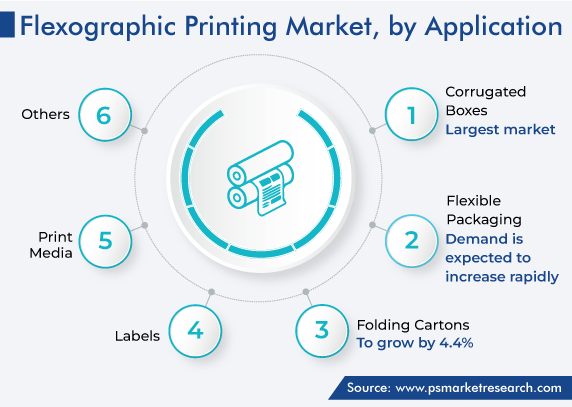

The corrugated packaging category holds the largest share within the application segment of the flexographic printing market, and it will likely witness 4.2% CAGR during the forecast period. This is because of the capability of this technology to easily create texts, labels, and graphics on brown corrugated boxes, which are frequently used for storing and shipping products. By utilizing flexographic printing on such boxes, retailers and manufacturers get the advantage of directly printing product details, brand elements, barcodes, logos, and other relevant information onto the packaging.

The packaging industry is propelled by the rising consumer demand for packaged products. Another major driver for this sector currently is the emerging trend of e-commerce, which is resulting in a notable surge in the need for packaging materials to protect and deliver goods. Additionally, the industry's expansion is augmented by the growing emphasis on environmental sustainability, which is urging companies to seek eco-friendly packaging solutions.

Industries can put unique and eye-catching characters and images on corrugated boxes for competitive advantages in branding and conveying product information. Additionally, as corrugated boxes are biodegradable and recyclable, they are an environment-friendly choice for packaging.

The capacity to print on flexible, non-rigid materials makes flexographic printing helpful when printing on rolls of materials utilized for plastic and paper bags. This printing technique is particularly well-suited for industries, by allowing for high-quality and efficient printing on plastic and paper bags.

Flexible packaging is expected to witness the fastest growth in the market during the forecast period. Such materials can be effortlessly folded, shaped, or bent, and this type of packaging provides benefits such as sustainability, preservation, and convenience, as this packaging requires less material as compared to traditional packaging. Additionally, it is lightweight, which results in lower transportation costs, and it extends the shelf life of food products by safeguarding it from oxygen and moisture. This is why it is used in diverse industries, such as personal care products, food & beverages, and pharmaceuticals. The constituent materials in flexible packaging encompass aluminum foil, plastic films, paper, and laminates, which are combined to form structures with barrier properties to protect the contents from light, oxygen, moisture, and various other external influences.

Folding cartons are expected to account for 4.4% CAGR over the forecast period. They are lightweight, due to which the demand for them is spiking. The rising consumption of packaged products as a result of the evolving lifestyle and changing eating habits majorly propels the usage of flexographic printing on folding cartons for food packaging.

Flexographic printing allows for quick drying and offers the advantage of using non-toxic inks. Therefore, it can be used on food packaging, such as beverage containers, food containers, milk cartons, and disposable cups. An essential aspect for physical carton and final package printing services is quality assurance. To meet the growing demand for packaged food & beverages, companies are exploring multi-site operations.

Flexographic printing is used on a diverse range of packaging materials, such as paper, plastics, and board. The increase in the per capita disposable income and the expansion of the population will contribute to the increase the demand for printed packaging for food products and e-commerce boxes. This is driven by the favorable attributes these materials impart to the contents, including a long shelf life, strong protection from the elements, and high safety for consumers.

While flexographic printing has a long history of printing folding cartons, the industry has only recently adopted central-impression presses for this purpose. A key example of these applications is pizza cartons, a task traditionally assigned to other printing methods. Notably, the ability to achieve multi-color printing with precise registration on wide-web surfaces has made flexographic printing increasingly appealing for various point-of-purchase folding carton applications.

Drive strategic growth with comprehensive market analysis

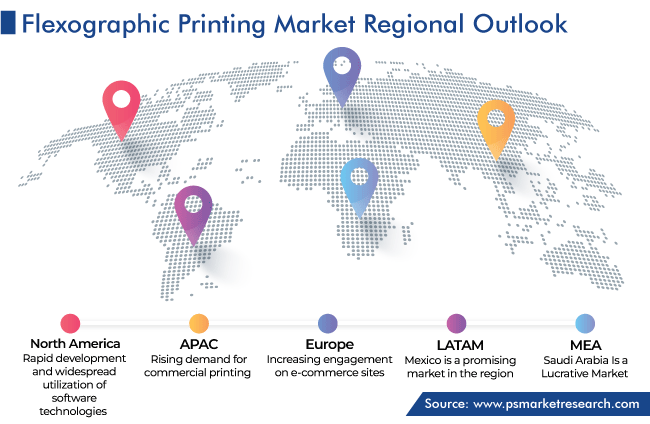

Asia-Pacific is projected to lead the market, with a share of 45%, during the forecast period. In emerging economies, including India, China, Thailand, Indonesia, and Vietnam, the rising demand for commercial printing is propelling the growth of the market. The speedy growth of the e-commerce sector in the region is another major driving force behind the growing use of flexographic printing. It is useful for producing labels and corrugated cardboards, which are extensively used in this industry.

According to Invest India, the Indian e-commerce market was worth over USD 55 billion in gross merchandise value in 2021 and expected to reach USD 350 billion by 2030. Therefore, the logistics sector in the region is a major consumer of printed labels and packaging, which is why its progress is a key driver for the market.

Hence, the leading players are entering the region through strategic partnerships, aiming to enhance their market presence. These alliances are designed to introduce the region to new and innovative technologies, thereby stimulating the adoption of flexographic printing machines during the forecast period.

North America is set to grow at a CAGR of 4.5% during the forecast period. The rapid development and widespread utilization of software technologies and microcomputers are raising the level of automation in the printing process. This aims to minimize human intervention and make the operation more efficient, at the same time reducing the requirement for materials, energy, and labor. Additionally, the improvements in make-ready and plate preparation processes, particularly in flexographic printing, are fueling automation within the industrial printing sector of North America and resulting in faster turnarounds.

Within North America, the cosmetics and food industries are increasingly focusing on sustainable, innovative, and eco-conscious packaging and printing solutions. This shift is aimed at effectively communicating the product's identity, while also being environment-friendly. The increasing prevalence of shopping on a growing count of e-commerce portals in the U.S. is positively influencing the market.

This report offers deep insights into the flexographic printing market, with size estimation for 2019 to 2030, the major drivers, restraints, trends and opportunities, and competitor analysis.

Based on Application

Based on Method

Based on Offering

Geographical Analysis

Browse Detailed Companies Insights

By 2030, the size of the market for flexographic printing will be USD 11,581.4 million.

Bobst Group SA holds the largest flexographic printing industry share.

Corrugated packaging dominates the market for flexographic printing.

Flexible packaging is the fastest-growing application in the flexographic printing industry.

Asia-Pacific is the largest market for flexographic printing.

The flexographic printing industry is driving by the rising demand for paper and plastic packaging.

The growing e-commerce sector propels the market for flexographic printing by driving the demand for corrugated boxes and other packaging materials.

Want a report tailored exactly to your business need?

Request CustomizationLeading companies across industries trust us to deliver data-driven insights and innovative solutions for their most critical decisions. From data-driven strategies to actionable insights, we empower the decision-makers who shape industries and define the future. From Fortune 500 companies to innovative startups, we are proud to partner with organisations that drive progress in their industries.

Working with P&S Intelligence and their team was an absolute pleasure – their awareness of timelines and commitment to value greatly contributed to our project's success. Eagerly anticipating future collaborations.

McKinsey & Company

IndiaOur insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws

Customize the Report to Align with Your Business Objectives

Request the Free Sample Pages