Market Statistics

| Study Period | 2019 - 2030 |

| 2024 Market Size | USD 9.8 Billion |

| 2030 Forecast | USD 19.8 Billion |

| Growth Rate(CAGR) | 12.3% |

| Largest Region | Asia-Pacific |

| Fastest Growing Region | North America |

| Nature of the Market | Fragmented |

Report Code: 12644

Get a Comprehensive Overview of the Recycled Elastomers Market Report Prepared by P&S Intelligence, Segmented by Type (Thermoset, Thermoplastic), Application (Automotive, Industrial, Healthcare, Consumer Goods), and Geographic Regions. This Report Provides Insights from 2019 to 2030.

| Study Period | 2019 - 2030 |

| 2024 Market Size | USD 9.8 Billion |

| 2030 Forecast | USD 19.8 Billion |

| Growth Rate(CAGR) | 12.3% |

| Largest Region | Asia-Pacific |

| Fastest Growing Region | North America |

| Nature of the Market | Fragmented |

Explore the market potential with our data-driven report

The global recycled elastomers market size stood at USD 9.8 billion in 2024, and it is expected to advance at a compound annual growth rate of 12.3% between 2024 and 2030, to reach USD 19.8 billion by 2030. This is primarily ascribed to the rising usage of elastomers in several industries for multiple purposes, stringent government rules, and increasing awareness of recycling benefits.

In addition, elastomers are widely adopted in the automotive and healthcare industries for the manufacturing of products such as tires, balloons, adhesives, and medical tubes. The surging demand for elastomer products augments the environmental issues, as these are non-biodegradable. The rapidly growing usage of elastomers generates problems such as huge land required for the dumping of used rubber waste from industries and because of the slow decomposition of elastomers, these hoard and generate harmful chemical gases that are injurious to the environment and health.

Thus, these are the key driving factors that lead companies to recycle them to meet customers’ needs and protect the environment and human life. Recycling is the only option because elastomer products take time to decompose. Devulcanization is a vital approach, in which at a particular level, ultrasonic amplitudes enable to break up of the three-dimensional network of vulcanized elastomers with heat and pressure. Also, the standard recycling approach is reducing the size into a small part that can be re-compound or reused.

Moreover, elastomers are polymeric materials that can be expanded up to a certain limit and return to their original shape. These are made up of rubber and elastomeric plastics, due to which these materials have huge requirements, especially in the consumer goods, medical, and tire industries. The huge demand for elastomers is leading market players to recycle them for reuse.

Furthermore, the surging penetration of EVs across the globe is increasing the need for elastomers. Almost 70% of the globally produced rubbers are used in making tires, and nearly 800 million tons of waste and tires are discarded every year globally, which have up to 60% of rubber content. This is due to the rising sales of automobiles. For instance, in 2022, the sales of automobiles increased by 3.4% as compared to the previous year. To reduce the volume of waste, companies are increasingly involved in recycling elastomers.

In addition, the demand for eco-friendly elastomers is rapidly growing, due to their rising usage in various industries. Recycling is the best option to save money & time, and growing awareness about the recycling benefits among users is forcing companies to recycle rubber products. Recycled elastomers are made up of waste such as gaskets, tires, and other rubber products. Also, the recycling process provides several benefits to the environment and decreases the requirement of virgin materials, and it also helps to reduce the waste that is dumped on the land.

The manufacturing process of elastomers is expensive and difficult as compared with other materials like polyethylene, polyurethane, and PVC. For the production of elastomers, machines are set at high temperatures in the presence of technicians, which is increasing their prices. Also, most raw materials of elastomers are derived from oil, due to which the prices of such materials are fluctuating when the oil price fluctuates. Thus, companies recycle elastomers and used recycled elastomers to avoid the production processes to save their time and money.

The surging population is driving the consumption of elastomers, due to their effective properties such as flexibility, strength, cost-effectiveness, and durability. These elastomers are utilized as per their qualities such as corrosion resistance, high heat resistance, and ease to recycle, which are the key driving factors escalating their need in developing countries, such as China, Brazil, and India. As these nations are generating high demand, companies are recycling rubber products to meet the increasing need. Thermosets and thermoplastics are the most adopted elastomers that are used in several industries in these economies.

The thermoset category is expected to hold a larger revenue share, over 60%, in 2022, and it is expected to witness a higher CAGR to maintain its position over the next few years. This is because thermosets are used in various industries such as automotive, electrical goods, construction, and aerospace. These are used in the manufacturing of various products such as tires, electrical housings, cell tower tops, circuit brakes, insulators, and disc brake pistons. Also, the thermoset’s features make it the best and most reliable option, where the tolerance of temperature is high.

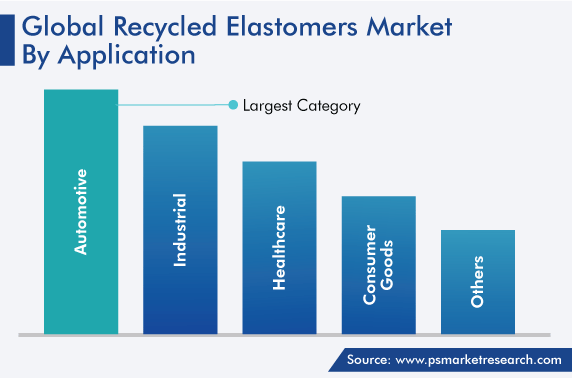

The automotive category accounted for the largest revenue share, over 30%, in 2022, and it is also expected to remain in its position during the forecast period. This is primarily ascribed to the rising usage of elastomers for the production of components that require high-temperature tolerance, such as tires, engine mounts, bushes, and gaskets. Due to this, the industry uses recycled elastomers to fulfill the demand and protect nature. Further, several governments and industries are working together to find the best way to recycle such products. Thus, the extreme usage of recycled materials in the automotive industry is escalating the growth of the market.

Drive strategic growth with comprehensive market analysis

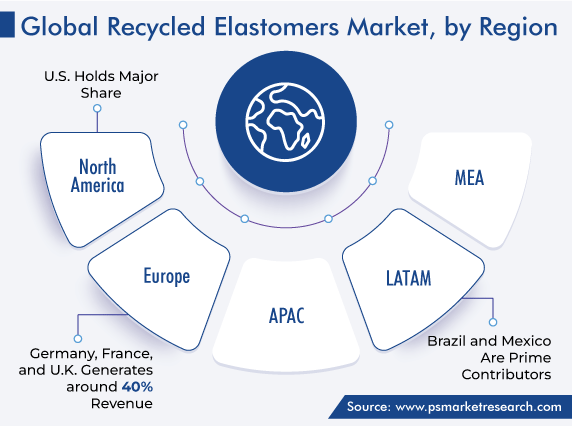

Globally, the APAC region held the largest revenue share in 2022, and it is also projected to remain the largest over the next few years. The regional market is growing due to the rising demand from end-use industries, such as automotive, consumer goods, and medical. Further, foreign countries are directly investing in this region because of the high availability of low-cost labor and a large volume of waste elastomers. The increasing government rules and the growing population are forcing the elastomer sector to enhance the recycling process.

Moreover, the rising demand for automobiles and consumer goods are boosting the need for recycled elastomers in the region. For instance, in India, the requirement for such products is growing due to the expansion of the automotive industry and their qualities such as lightweight, high performance, and elasticity, along with the changing perceptions of the industry on using recycled automotive components and tires.

In addition, businesses are using recycling and conventional technology methods to fulfill the market demand. For instance, in July 2022, tire and rubber manufacturing companies joined the national conference on the circular economy in the tire and rubber industry in India, to discuss the EPR draft policy, how to utilize waste tires, and eco-friendly recycling approach for tires.

In APAC, China is the largest market, due to the growing population, surging need for commercial and passenger cars, rising consumption of consumer goods, high import and export, and increased industrial output in the country. Thus, the mounting need for elastomers is forcing companies to adopt the recycling approach to meet the demand in the nation.

The North American recycled elastomers market is expected to grow at a significant growth rate over the next few years. This is because the automotive and consumer goods industries are creating a high need for recycled elastomers in the region. For instance, in 2019, as per the U.S. Tire Manufacturers Association (USTMA), around 76% of scrap tires were recycled to produce different items, such as automotive products, rubber-modified asphalt, tire-derived fuel, and mulch for landscaping.

Based on Type

Based on Application

Geographical Analysis

The recycled elastomers market size stood at USD 9.8 billion in 2024.

During 2024–2030, the growth rate of the recycled elastomers market will be 12.3%.

Automotive is the largest application area in the recycled elastomers market.

The major drivers of the recycled elastomers market include the increasing need for recycled elastomers in several industries, due to their high strength, durability, high-temperature tolerance, elasticity, and flexibility; the rising sales of automobiles and consumer goods in developing countries; the presence of stringent government rules, and the surging awareness of recycling benefits.

Want a report tailored exactly to your business need?

Request CustomizationLeading companies across industries trust us to deliver data-driven insights and innovative solutions for their most critical decisions. From data-driven strategies to actionable insights, we empower the decision-makers who shape industries and define the future. From Fortune 500 companies to innovative startups, we are proud to partner with organisations that drive progress in their industries.

Working with P&S Intelligence and their team was an absolute pleasure – their awareness of timelines and commitment to value greatly contributed to our project's success. Eagerly anticipating future collaborations.

McKinsey & Company

IndiaOur insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws

Customize the Report to Align with Your Business Objectives

Request the Free Sample Pages