Market Statistics

| Study Period | 2019 - 2030 |

| 2024 Market Size | USD 15.1 Billion |

| 2030 Forecast | USD 20.1 Billion |

| Growth Rate(CAGR) | 4.9% |

| Largest Region | Asia-Pacific |

| Fastest Growing Region | Asia-Pacific |

| Nature of the Market | Fragmented |

Report Code: 12152

Get a Comprehensive Overview of the Metal Cleaning Chemicals Market Report Prepared by P&S Intelligence, Segmented by Type (Aqueous, Solvent), Ingredient (Surfactants, Chelating Agents, Solvents, pH Regulators, Solubilizers), Metal Type (Steel, Aluminum, Copper), End User (Automotive, Manufacturing, Aerospace, Healthcare, Construction), and Geographic Regions. This Report Provides Insights From 2019 to 2030.

| Study Period | 2019 - 2030 |

| 2024 Market Size | USD 15.1 Billion |

| 2030 Forecast | USD 20.1 Billion |

| Growth Rate(CAGR) | 4.9% |

| Largest Region | Asia-Pacific |

| Fastest Growing Region | Asia-Pacific |

| Nature of the Market | Fragmented |

Explore the market potential with our data-driven report

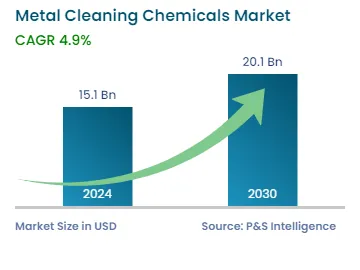

The global metal cleaning chemicals market revenue was USD 15.1 billion in 2024, which will reach USD 20.1 billion by 2030, advancing at 4.9% CAGR between 2024 and 2030.

Many impurities could be present on metallic surfaces, such as grease, corrosive oxides, oils, and a range of other organic and inorganic materials. This is why these chemicals are used in multiple industries, such as automotive, aerospace, and manufacturing, to prevent metal deterioration, protect machinery and equipment, and, ultimately, ensure damage prevention and optimal performance.

Essentially, these chemicals are important in preventing metals from the long-term effects of corrosion, hard water, and lubricating oils. Corrosion can be removed by using hydrochloric acid (aka muriatic acid) and oxalic acid. Hard water can be treated with the help of ammonia, borax, calcium hydroxide, or trisodium phosphate, along with sodium carbonate. Moreover, metallic surfaces can be guarded against lubricating oils with the use of anti-wear additives, specifically zinc dialkyldithiophosphate (ZDDP).

In the fouling process, unwanted materials, such as organic substances, including algae, microorganisms, animal fats, and hydrocarbons; as well as inorganic substances, such as hydroxides, oxides, carbonates, sulphides, sulphates, and silicates; accumulate on solid surfaces. To prevent this, industries such as automotive, aerospace, and manufacturing use a range of chemicals. The selection of the appropriate product for this purpose depends on the surface condition and the specific contaminants needed to be removed.

The construction and automotive industries are expanding, due to which the demand for these agents is growing. Because these chemicals are needed in the production of body parts for automobiles, there would be a significant increase in their usage as the global manufacturing of vehicles continues to surge. Moreover, in the construction sector, they are required to remove metallic scales and corrosive elements. Organizations that require exceptional finishing in architectural shaping, such as the creation of showpieces, also use these agents to a great extent.

Surging Adoption of Eco-Friendly Impurity Removal Agents for Metals

The market for metal cleaning chemicals is set to showcase a noticeable growth rate due to the surging demand for eco-friendly solutions. All over the world, governments are focusing on sustainable development, due to which industries are shifting away from the common solvent-based cleaners, which contain hazardous elements. This is leading to the need for sustainable, environment-friendly chemicals that are biodegradable, non-toxic, and non-flammable.

Moreover, the rise in the need for eco-friendly solutions is owing to the growing awareness among businesses and consumers of the deadly effects of the traditional ones on human health and the environment. The demand for green detergents, water-based solutions, and bio-based solvents is on the rise due to their reduced impact on the environment, low toxicity, and enhanced worker safety.

The market is also experiencing a revolution with the advent of cleaning technologies that offer advanced surface preparation ability, shorter cleaning times, and greater effectiveness. Scientists have even used nanotechnology for developing metal cleaning solutions that result in effective microscopic cleaning, by eliminating even the smallest particles from metallic surfaces. Further, the demand for nanotechnology-based solutions is surging because of their superior efficacy, effectiveness, and low environmental impact.

Moreover, the automotive, manufacturing, and construction industries in developing countries are giving priority to these cleaning solutions. Such countries are using cutting-edge production technologies and implementing strict quality standards to ascertain the reliability, safety, and efficacy of their products. Additionally, the increasing per capita income and changing lifestyles in emerging economies have led to a higher dependence on gadgets, home appliances, and cars, thus driving the demand for effective and eco-friendly metal cleaning chemicals.

Aqueous cleaners, with a global revenue share of 75%, dominated the cleaner type segment of the metal cleaning chemicals market in 2022. This category is also expected to dominate the market in terms of value and volume during the projection period.

These solutions are non-flammable, have low or no concentrations of volatile organic compounds (VOC), and pose low health risks. These solutions use stirring, heat, and additives to clean impurities off metals’ surfaces.

Moreover, sequestrants and inhibitors are the second-fastest-growing category. Sequestrants are water-based conditioners that aid in stopping metal ions from accumulating and precipitating in alkaline solutions. They help in maintaining water hardness and destroying oxide layers, without any effect on the base metal. Their aim is to add metals from dissolved oxide to calcium and magnesium, to make soluble complexes. Some examples of sequestrants are tripolyphosphates, organic phosphates, and salts of polycarbonic acids, such as sodium gluconate.

Furthermore, when it comes to efficiency at cleaning ferrous metals, aqueous metal cleaning solutions use inhibitors due to their property of saving metallic components from corrosion.

The demand for aqueous cleaners based on eco-friendly and low-VOC technologies is set to rise in the coming years because governments around the world are focusing on sustainable development.

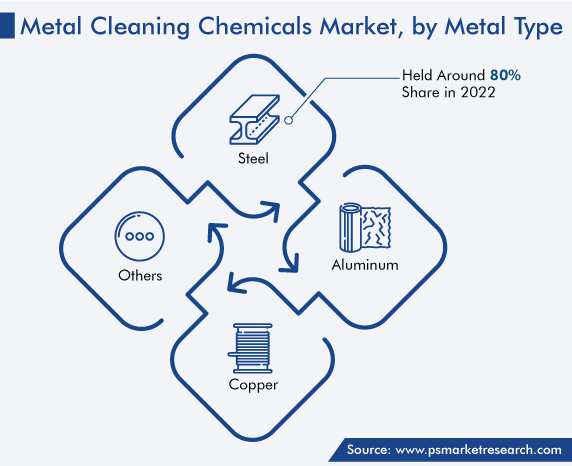

Based on metal type, the steel category dominates the market in terms of revenue.

Globally, steel production is on the rise as economies are expanding and its properties are incomparable. Steel is used in a variety of places, such as powerline towers, gas pipelines, machinery & equipment, and military systems. Moreover, steel holds the largest share because of its higher affordability as compared to aluminum. Moreover, steel requirements in the industrial and construction sectors in developing countries, such as Brazil, China, India, Iran, and Mexico, are burgeoning.

Furthermore, aluminum is set to display the fastest growth, owing to its increasing production all over the world. In general, steel is stronger, but when it comes to fabricating lightweight products with great strength, aluminum is preferred. This is because it possesses a superior strength-to-weight ratio. Additionally, its malleability, elasticity, and stronger rust resistance augment its appeal.

Under the end user segment, in 2022, the industry was dominated by manufacturing, with a revenue share of 40%. This is due to the increasing demand for metallic products with outstanding performance, such as heavy machinery, equipment, reactors, tanks, and tools.

Moreover, the healthcare industry generates noticeable revenue as it is mandated to give topmost priority to the sterility and safety of equipment, so that professionals and patients do not contract nosocomial infections. In order to reduce cross-contamination, enhance working lifespan, and reduce medical waste, healthcare facilities use these chemicals to great extent.

Furthermore, the automotive and aerospace sectors are significant users of these chemicals. It is important for these industries to enhance the lifespan of various metallic components, by preventing wear and tear, in order to use cars and aircraft to their maximum efficiency and prevent accidents due to metal fatigue.

Polishing and cleaning are crucial in the manufacturing and assembly line operations in the automotive industry. During these operations, aqueous metal cleaners are used to eliminate grease, oil, and heavy dust from brake parts. With the advent of new technologies, auto parts can now be cleaned using spray washers, thus eliminating the need for brushing or scrubbing by hand.

Drive strategic growth with comprehensive market analysis

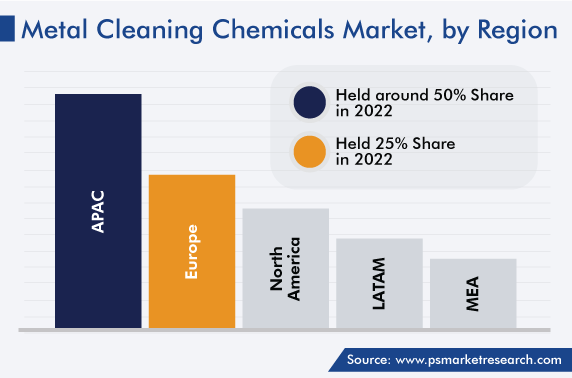

Asia-Pacific is set to witness the highest CAGR throughout the prediction period, of 6%. This has a lot to do with the surging industrialization rate and increasing metal production in the developing economies in the region. The progressing manufacturing sector, particularly in China, India, and Japan, will drive the market expansion in the years to come.

Moreover, Europe is set to witness significant growth owing to its well-developed manufacturing sector. People in Europe are leaning toward high-quality and long-lasting goods, which is further driving investments in the chemicals used for metal cleaning. The government initiatives and pro-business policies in Europe are helping in corporate growth, especially in Germany, France, and the U.K., which hold noticeable shares because of their high-volume metallic goods consumption.

Furthermore, North America will show considerable growth during the projection period due to the expansion of the manufacturing sector and the strict regulations governing product quality. Additionally, the surging production of metal cleaning chemicals will aid the market expansion in the region.

Likewise, the Middle East and African region is set to see good growth in the market due to the escalating industrial activity and the harsh regulations prohibiting the usage of hazardous chemicals.

Latin America is also expected to remain competitive in terms of exports because of the sustained economic expansion and the high consumer demand for top-quality finished goods.

This fully customizable report gives a detailed analysis of the metal cleaning chemicals industry from 2019 to 2030, based on all the relevant segments and geographies.

Based on Type

Based on Ingredient

Based on Metal Type

Based on End User

Geographical Analysis

By 2030, the market for metal cleaning chemicals will reach USD 20.1 billion.

The aqueous bifurcation dominates the metal cleaning chemicals industry.

Nanotechnology and eco-friendly agents are trending in the market for metal cleaning chemicals.

The manufacturing sector leads the metal cleaning chemicals industry.

APAC will grow the fastest in the market for metal cleaning chemicals.

Want a report tailored exactly to your business need?

Request CustomizationLeading companies across industries trust us to deliver data-driven insights and innovative solutions for their most critical decisions. From data-driven strategies to actionable insights, we empower the decision-makers who shape industries and define the future. From Fortune 500 companies to innovative startups, we are proud to partner with organisations that drive progress in their industries.

Working with P&S Intelligence and their team was an absolute pleasure – their awareness of timelines and commitment to value greatly contributed to our project's success. Eagerly anticipating future collaborations.

McKinsey & Company

IndiaOur insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws

Customize the Report to Align with Your Business Objectives

Request the Free Sample Pages