Report Code: 11447 | Available Format: PDF | Pages: 143

Extrusion Coating Market Research Report: By Material Type (Low-Density Polyethylene, Ethylene-Vinyl Acetate, Polypropylene), Substrate (Paper & Paperboard, Polymer Film, Aluminum Foil), Application (Liquid Packaging, Flexible Packaging, Commercial, Photographic)- Global Industry Size, Share, Development, Growth, and Demand Forecast to 2023

- Report Code: 11447

- Available Format: PDF

- Pages: 143

- Report Description

- Table of Contents

- Market Segmentation

- Request Free Sample

Valued at $3,703.8 million in 2017, the global extrusion coating market is projected to surpass $4,759.3 million by 2023, witnessing a CAGR of 4.2% between 2018 and 2023.

Asia-Pacific (APAC) is expected to witness the fastest growth in the industry during the forecast period. This can be mainly attributed to increasing demand for extrusion coating materials for packaging applications in different industries, such as food and beverage, healthcare, and personal care.

Fundamentals Governing Extrusion Coating Market

Increasing use of polypropylene (PP) in food and beverage packaging is being observed as the major trend in the extrusion coating market. It is tough and flexible, and can be used as a plastic or fiber in various plastic end-use applications. The recyclability characteristic of PP is another factor that encourages food and beverage companies to adopt this material for product packaging. Owing to such properties, the food and beverage industry is increasing usage of PP for packaging applications.

Increasing income levels, changing lifestyle, and growing population are the factors boosting the demand for consumer goods, electronic items, personal care products, and sporting goods, globally. Extrusion coating materials are used in the manufacturing of packaging films, papers, and paperboards, required for the packaging of consumer products. Growing demand for different types of packaging solutions from different industries is contributing to the growth of the extrusion coating market.

The demand for extrusion coating materials in emerging economies, such as APAC, Latin America (LATAM), and Middle East and Africa (MEA), is on the rise. This is attributed to the rapid growth of industries such as food and beverage, healthcare, personal care, electronics, and consumer goods, which make use of packaging materials for their products. For instance, as per the International Trade Administration (ITA), the Indian healthcare industry stood at $110 billion in 2016 and is anticipated to reach $280 billion by 2020, owing to the rapidly increasing demand for healthcare products and services in the country. Thus, rising demand for extrusion coating materials in emerging economies is providing ample growth opportunities to the players in the extrusion coating market.

Extrusion Coating Market Segmentation Analysis

The low-density polyethylene (LDPE) category held the largest revenue share among all material types in 2017 in the extrusion coating market. This is ascribed to increasing demand for LDPE for the production of films, which are used as packaging materials, bags, and sacks.

The polymer film category is projected to grow fastest among all substrates over the forecast period, on account of growing demand for flexible packaging solutions in various industries (e.g., food and beverage, personal care, and healthcare). These industries make use of polymer films to protect their products from shock, vibration, and surface abrasion.

Liquid packaging was the largest application area of extrusion coating materials during the historical period in the extrusion coating market. This is attributed to the growing use of extrusion coating materials in liquid packaging to increase the saleability of different types of liquid and semi-solid food items, such as milk, juice, and sauce.

| Report Attribute | Details |

Historical Years |

2013-2017 |

Forecast Years |

2018-2023 |

Market Size by Segments |

Material Type, Substrate, Application |

Market Size of Geographies |

U.S., Canada, Germany, France, U.K., Italy, Spain, China, Japan, India, Brazil, Mexico, Saudi Arabia, South Africa |

Explore more about this report - Request free sample

Global Scenario of Extrusion Coating Market

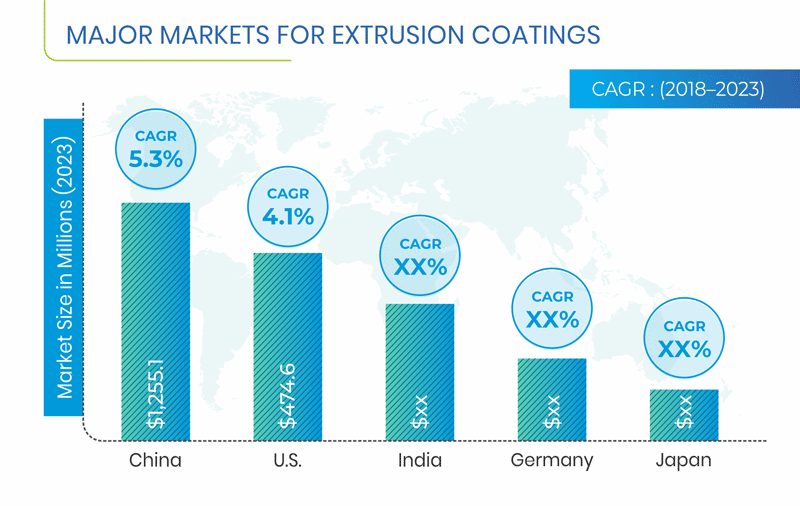

APAC was the largest region for the global extrusion coating market during the historical period and is expected to maintain the trend during the forecast period as well. This can be mainly attributed to the ongoing industrialization and increasing disposable income in the region, which boost the growth of different industries utilizing extrusion coating materials for packaging purposes.

Also, the market is expected to witness the fastest growth in the APAC region during the forecast period. Various countries of the region, including China, Japan, India, and South Korea, are expected to witness strong economic growth in the near future, owing to huge government spending on food safety, health, and hygiene.

Considering the future industry scenario, China is expected to lead the APAC region, generating revenue worth $1,255.1 million in 2023.

Competitive Landscape of Extrusion Coating Market

Some of the major players operating in the extrusion coating market are DowDuPont Inc., LyondellBasell Industries N.V., Exxon Mobil Corporation, SABIC, and Chevron Phillips Chemical Company LP, INEOS Group Holdings S.A., Mondi Group, Qenos Pty. Ltd., and Westlake Chemical Corporation.

Recent Strategic Developments of Major Extrusion Coating Market Players

In recent years, key players in the extrusion coating market have taken several strategic measures such as product launches and geographical expansions to gain a competitive edge in the industry. For instance, in March 2018, Chevron Phillips Chemical Company LP announced introduction of feedstock and commencement of operations of a new ethane cracker at its Cedar Bayou facility in Baytown, Texas, to meet the growing demand for ethylene and polyethylene for the production of various consumer and industrial products.

Moreover, in October 2017, Borealis AG and Borouge, plastic solutions providers, launched Anteo, a group of linear low-density polyethylene (LLDPE) packaging grades to cater to the global packaging market.

Market Size Breakdown by Segment

The Extrusion Coating Market report offers comprehensive market segmentation analysis along with market estimation for the period 2013–2023.

Based on Material Type

- Low-density polyethylene (LDPE)

- Ethylene-vinyl acetate (EVA)

- Polypropylene (PP)

Based on Substrate

- Paper and Paperboard

- Polymer Film

- Aluminum Foil

Based on Application

- Liquid Packaging

- Flexible Packaging

- Commercial

- Photographic

Geographical Analysis

- North America

- U.S.

- Canada

- Europe

- Germany

- U.K.

- France

- Italy

- Spain

- Asia-Pacific (APAC)

- China

- Japan

- India

- Latin America (LATAM)

- Brazil

- Mexico

- Middle East and Africa (MEA)

- South Africa

- Saudi Arabia

Want a report tailored exactly to your business strategy?

Request CustomizationWant an insight-rich discussion with the report author?

Speak to AnalystOur dedication to providing the most-accurate market information has earned us verification by Dun & Bradstreet (D&B). We strive for quality checking of the highest level to enable data-driven decision making for you

Our insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

With 24/7 research support, we ensure that the wheels of your business never stop turning. Don’t let time stand in your way. Get all your queries answered with a simple phone call or email, as and when required

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws