Market Statistics

| Study Period | 2019 - 2030 |

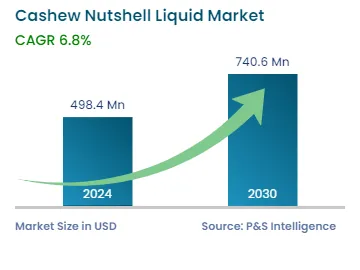

| 2024 Market Size | USD 498.4 Million |

| 2030 Forecast | USD 740.6 Million |

| Growth Rate(CAGR) | 6.8% |

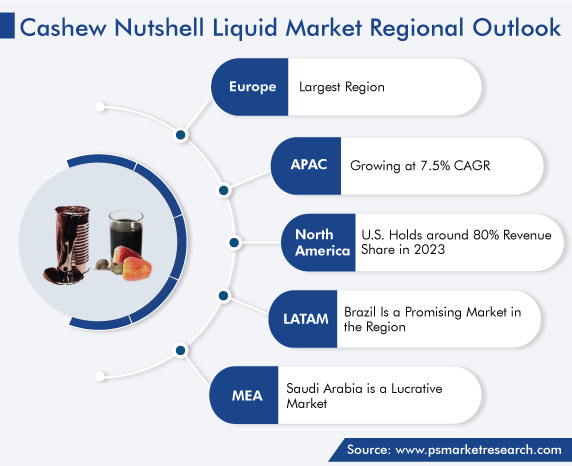

| Largest Region | Europe |

| Fastest Growing Region | Asia-Pacific |

| Nature of the Market | Fragmented |

Report Code: 12710

Get a Comprehensive Overview of the Cashew Nutshell Liquid Market Report Prepared by P&S Intelligence, Segmented by Product (PF Resins, Epoxy Modifiers & Resins, Epoxy Curing Agents, Surfactants, Polyols & NCO-Blocking Agents, Friction Materials), Application (Adhesives, Coatings, Foams & Insulation, Laminates, Friction Linings, Personal Care Products), and Geographic Regions. This Report Provides Insights From 2019 to 2030.

| Study Period | 2019 - 2030 |

| 2024 Market Size | USD 498.4 Million |

| 2030 Forecast | USD 740.6 Million |

| Growth Rate(CAGR) | 6.8% |

| Largest Region | Europe |

| Fastest Growing Region | Asia-Pacific |

| Nature of the Market | Fragmented |

Explore the market potential with our data-driven report

The cashew nutshell liquid market was valued at USD 498.4 million in 2024, which is expected to reach USD 740.6 million by 2030, growing at a CAGR of 6.8% during 2024–2030.

A valuable ingredient, it is used to make resins, friction materials, paints, varnishes, laminates, and adhesives, among many other things. With the expanding demand for these formulations and the development of new products with this ingredient, the market continues to grow.

The need for bio-based and environment-friendly products is rising as people grow more ecologically aware. Since it is a renewable and environmentally beneficial resource, it appeals to enterprises trying to lessen their ecological impact and carbon footprint.

The utilization of cashew nutshell liquid, a byproduct of cashew nut processing, in industries fits well with the idea of the circular economy, where waste is minimized, resources are preserved, and materials are reused or recycled.

The lower toxicity of these goods compared to some petroleum-based alternatives makes them a popular choice. These items are chosen by sectors that place a high priority on health and safety, for which they focus on lowering the danger of chemical exposure.

Additionally, the technological developments in processing methods and application areas may create new opportunities and markets. The economic feasibility of such substances may be enhanced by improved extraction processes and purifying procedures, as well as performing R&D on newer possible applications.

The consumption of this ingredient may also be boosted by government policies that encourage the adoption of environment-friendly substances and natural resources. A climate that is favorable for the market can be created by providing incentives and subsidies and implementing rules that encourage the use of bio-based products.

Moreover, being sourced from nature makes cashew nutshell liquid a more-affordable option than petrochemicals for the production of resins and other products. Hence, there might be more interest in it when crude oil prices are high.

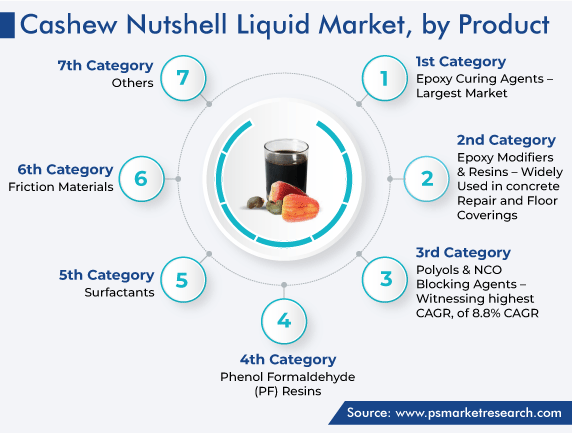

Polyols & NCO-blocking agents held a significant share, of 20%, in 2023, and this category is expected to witness the highest CAGR, of 8.8%, over this decade.

This is credited to the high-volume consumption of this raw material in the production of bio-based polyurethane, which has extensive industrial applications. Foams, coatings, adhesives, sealants, and elastomers are just a few applications of the adaptable polymer polyurethane.

These goods are frequently made from polyols, which are substances containing numerous hydroxyl groups. They are among the principal reactants, which, when mixed with isocyanates (NCO groups), undergo a chemical process to produce polyurethane.

Anacardia acid, which is abundant in cashew nutshell liquid and may be converted to cardanol, is a key resource. It is utilized to create a bio-based substitute for polyols derived from petrochemicals.

In the creation of one-component polyurethane adhesives and sealants, isocyanate (NCO) blocking agents are used. They serve as stabilizers, maintaining excellent adhesive performance and increasing the shelf life, by preventing the early interaction of the isocyanate component with other chemicals in the formulation.

Products made of polyurethane are incredibly adaptable and used in a variety of sectors. Polyurethane foams offer insulation and protection in the construction industry and improve comfort and durability in automobile applications. The cushioning capabilities of polyurethane foams are advantageous for furniture. Polyurethane coatings and adhesives are also used in the electronics industry for protection, while polyurethane sealants are used in packaging to guarantee safe delivery.

In all these applications, PUs are shielded against premature curing by NCO blocking agents. The highly reactive, less toxic, and environment-friendly nature of cashew-nutshell-liquid-based NCO blocking agents makes them superior to conventional NCO blocking agents in a number of ways. Thus, in an expanding market for eco-friendly products, nature-based polyols and NCO blocking agents are seen as being more eco-friendly than conventional petroleum-based products.

The epoxy curing agents category is also expected to showcase significant growth till 2030.

Due to the superior mechanical, chemical, and adhesive qualities of epoxy resins, they are widely utilized in many sectors; epoxy curing agents are crucial ingredients in their formulations.

Natural phenolic chemicals, such as cardanol and cardol, which can be used as epoxy curing agents, are abundant in cashew nutshell liquid. The crosslinking and curing of epoxy resins are facilitated by these phenolic compounds. Epoxy curing agents developed from cashew nutshell liquid have good chemical resistance, thermal stability, and reactivity, which improve the overall performance of epoxy-based products.

There are numerous industrial uses for epoxy resins and, in turn, for the curing agents that go into them. They are employed in electronic encapsulation, to preserve delicate components; coatings, to defend against corrosion and abrasion; adhesives, for strong bonding among various materials; and composites, for lightweight, high-strength construction. The adaptability of epoxy systems is the key factor propelling the need for natural curing agents, including those derived from the liquid found in cashew nutshells.

Environmental responsibility is one of the main factors behind the significant increase in the usage of epoxy curing agents containing bio-based ingredients. Utilizing cashew nutshell liquid as an ingredient for epoxy curing agents encourages sustainability and lessens the reliance on curing agents derived from fossil fuels, in line with the rising demand for green and bio-based materials.

Epoxy curing agents made from this raw material are an attractive choice for manufacturers and clients who care about the environment, because they are bio-based, non-toxic, and biodegradable.

Additionally, chemical engineering innovations and ongoing research have produced superior epoxy curing agents from cashew nutshell liquid, with improved characteristics, such as improved heat resistance, due to which epoxy resins can sustain higher temperatures, without degrading. Another key advantage is better water resistance, which enhances their suitability for use in wet or humid conditions.

The category's expansion is further fueled by manufacturers' ongoing exploration of novel formulations and optimization of the production techniques to satisfy certain application needs.

The ratio of cardanol and cardol is changed to modify epoxy resins, to improve their qualities and customize them for various purposes. Such cardanol-based modifiers can improve epoxy resins' adhesion, flexibility, and impact resistance, to make them appropriate for numerous applications, such as adhesives, coatings, and composites.

Epoxy resins and modifiers are used in a variety of sectors. For concrete repair and floor coverings in construction, they improve epoxy's characteristics. Additionally, the coatings sector depends on them for corrosion protection, while the adhesives and sealants business benefits from increased bond strength. They are also utilized in aerospace and automotive composites, protective coatings, as well as electronics for encapsulating. The reactive phenolic compounds in cashew nutshell liquid interact with the unreacted epoxide groups in the epoxy resin prior to generating bonds, which results in the formation of a flexible, long-lasting, cross-linked network.

Drive strategic growth with comprehensive market analysis

The cashew nutshell liquid market is dominated by Europe. Many regional countries have well-established industries that use cashew nutshell liquid and its derivatives. Among them are automobile, coatings, adhesives, electronics, and construction. Additionally, promoting sustainable practices across a range of businesses has been a priority for European nations. The adoption of bio-based and renewable materials is being emphasized strongly as part of efforts to reduce the carbon footprint and the reliance on fossil fuels.

European consumers are increasingly looking for green and eco-friendly items. Consumer tastes have changed in favor of goods with a weaker environmental impact as a result of the growing consumer awareness of environmental issues.

Products made in Europe are not only consumed locally but also exported to other parts of the world. The established trade linkages and export capabilities of the continent have thus enhanced its market dominance.

The production and consumption of such goods have attracted the attention of European nations with the constant research and innovation. This has increased the need for this raw material by leading to the identification of new applications and improved formulations.

The Asia-Pacific region held a significant share, of 25% in 2023, and its revenue contribution is expected to witness a CAGR of 7.5% during 2023–2030.

The increasing rate of industrialization and the resulting growth in manufacturing activities have significantly fueled the market in the APAC region. The region's economic growth has led to a rising demand for a number of products and materials ultimately made from cashew nutshell liquid, such as solvent-based resins and coatings. Automotive, construction, electronics, and agriculture are just a few of the industries where cashew-nutshell-liquid-based products are used.

Further, one of the biggest cashew nut producers in the world is the Asia-Pacific region, and as the amount of cashew nuts processed rises, so will the volume of this substance available as a byproduct, thus opening up numerous prospects for its use.

This report offers deep insights into the cashew nutshell liquid industry, with size estimation for 2019 to 2030, the major drivers, restraints, trends and opportunities, and competitor analysis.

Based on Product

Based on Application

Geographical Analysis

Want a report tailored exactly to your business need?

Request CustomizationLeading companies across industries trust us to deliver data-driven insights and innovative solutions for their most critical decisions. From data-driven strategies to actionable insights, we empower the decision-makers who shape industries and define the future. From Fortune 500 companies to innovative startups, we are proud to partner with organisations that drive progress in their industries.

Working with P&S Intelligence and their team was an absolute pleasure – their awareness of timelines and commitment to value greatly contributed to our project's success. Eagerly anticipating future collaborations.

McKinsey & Company

IndiaOur insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws

Customize the Report to Align with Your Business Objectives

Request the Free Sample Pages