Report Code: 10235 | Available Format: PDF

Waste Heat Recovery Market Revenue Forecast Report: Size, Share, Recent Trends, Strategic Developments, Segmentation Analysis, and Evolving Opportunities, 2024-2030

- Report Code: 10235

- Available Format: PDF

- Report Description

- Table of Contents

- Request Free Sample

Market Overview

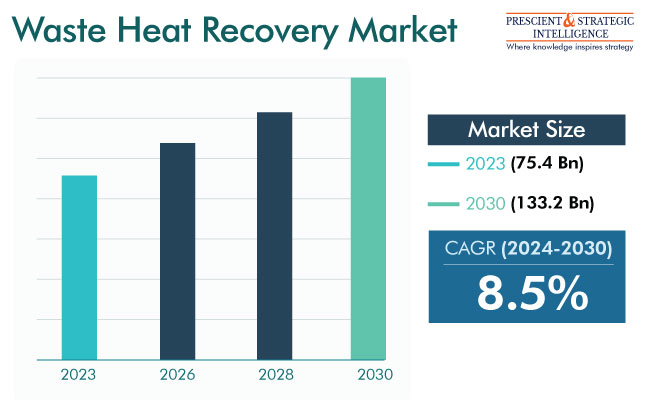

The waste heat recovery market revenue is estimated at USD 75.4 billion in 2023, and it will advance at a CAGR of 8.5% during 2024–2030, to reach USD 133.2 billion by 2030. This can be attributed to the increasing concern for greenhouse gases (GHG). Along with this, the growing industrialization level is resulting in the increasing requirement for energy, and the increasing electricity prices drive the world to produce it sustainably.

Growing Environmental Concerns Are Key Market Driver

Climate change presents a great challenge for economic, political, social, and environmental dimensions worldwide. The most-cost-effective and reliable approach to mitigating carbon emissions and saving on expenses is enhancing energy efficiency. Delivering energy for sustainable economic development is a shared goal of both developed and developing countries. Manufacturing facilities emit substantial heat during their operations, while contributing to a heightened carbon footprint and adverse environmental consequences. Waste heat recovery systems play a crucial role in elevating the overall energy efficiency of industrial manufacturing processes by reducing the need for fossil fuels to produce primary electricity.

According to the UN Habitat, cities are the chief contributors to climate change. They consume 78% of the world’s energy and produce more than 60% of the GHG emissions.

Preheating Category Dominates Market

As the recovered heat can be used to reduce energy costs, enhance energy efficiency, and lower GHG emissions, the preheating category is dominating the market. This is because this process has applications in metal furnaces, large boilers, compact boilers, compact industrial furnaces, and high-temperature kilns. The waste heat is transferred to a medium or fluid, which can then be used to generate steam to drive a turbine in a manufacturing facility. Additionally, in the copper and aluminum industries, the gases produced after recovery can be utilized to preheat the stock. The advantage of this is a reduction in the risk of explosions that can be caused by entrapped water vapor.

By using waste heat instead of additional energy sources, such as electricity and fossil fuels, companies can lower their operational expenses, thus making them more competitive in the market. This is the key reason driving the usage of waste heat recovery systems for preheating applications among heat- and energy-intensive industries.

The adoption of waste heat recovery systems for power and steam generation is increasing because of the rising electricity and fuel costs brought on by inflation. Additionally, the continued attempts to minimize GHG emissions are a key driver for the market across the globe.

Cement Industry Is Growing Rapidly as an End User

During the forecast period, the cement category is expected to witness rapid growth in the end user segment. In the cement industry, the demand for waste heat recovery systems is propelled by the rapid global growth of the construction sector in numerous emerging economies. This growth in India, China, and Indonesia is mostly being witnessed in the educational, social, retail, medical, and residential sectors.

Another major portion of the market revenue comes from the chemical and petrochemical industry, which utilizes the waste heat recovery technology for refining, thermal cracking, and catalytic treatment. Petroleum refining industry is highly energy-intensive, as the generation of waste heat is extensive due to the existence of processes such as distillation, cracking, reforming, and hydrotreating. A high temperature is required for these processes, and, as a result, waste heat is generated from fluid catalytic cracking units, crude distillation units, and other refining units.

Similarly, in the metal production and casting industry, this technology plays a vital role in improving energy efficiency and reducing environmental impact. Process such as smelting, refining, and molding, all of which generate a large amount of waste heat, characterize this industry. The advancements in the waste heat recovery technology now being implemented here include thermoelectric materials, heat exchangers, and combined heat and power (CHP) systems. Governments often provide incentives, tax credits, and grants as a way to motivate heat-intensive businesses and industries to embrace energy-efficient technologies, including systems designed for recovering waste heat.

The growth of the paper and pulp industry also plays an important role in the waste heat recovery market advance. This is due to its energy-intensive processes, such as pulping, bleaching, drying, and papermaking, which result in the generation of vast amounts of waste heat. In the paper and pulp sector, CHP applications are often the focus of waste heat recovery systems. CHP systems simultaneously produce electricity and useful thermal energy (hot water or steam) from the recovered waste heat. Utilizing waste heat for both power production and industrial processes can increase the overall energy efficiency.

According to the International Energy Agency (IEA), the industrial sector consumed 37% of the global energy in 2022, compared to 34% in 2002. The increase in the usage of energy over the last 10 years has been driven largely by the continuously rising production in energy-intensive industries. Thus, the substantial efforts of governments and industrialists to lower their consumption of electricity will propel the market over the forecast period.

| Report Attribute | Details |

Market Size in 2023 |

USD 75.4 Billion |

Revenue Forecast in 2030 |

USD 133.2 Billion |

Growth Rate |

8.5% CAGR |

Historical Years |

2017-2023 |

Forecast Years |

2024-2030 |

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

Explore more about this report - Request free sample

Heat Exchanger Technology Is Widely Used for Waste Heat Recovery

Hot exhaust gases are released into the atmosphere in many industrial processes. Heat exchangers can be used to capture this heat and transfer it to another medium, such as water or air. The recovered heat can be used for preheating incoming process fluids, space heating, or generating steam for additional processes. To increase the energy efficiency, recuperators, which transfer the heat from exhaust gases to the incoming process air or fluid; and regenerators, which store heat in a medium and then release it to the incoming fluid; are used.

Some of the Leading Players in Waste Heat Recovery Market Are:

- ABB Ltd.

- Ormat Technologies

- Harbin Electric International Company Ltd.

- Mitsubishi Hitachi Power Systems

- Dongfang Electric Corporation

- Siemens AG

- General Electric Company

- Amec Foster Wheeler PLC

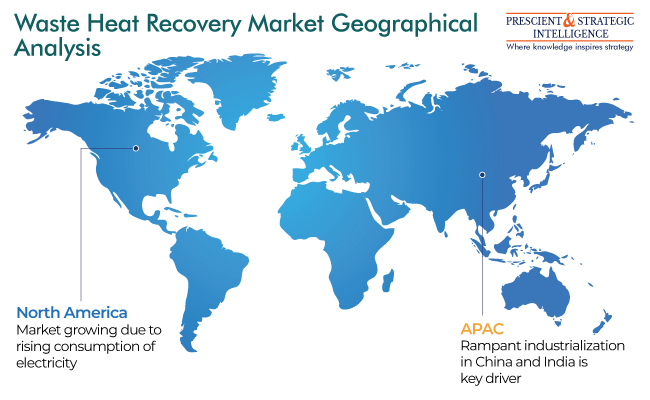

Fastest-Growing Market Is Asia-Pacific

The Asia-Pacific region is expected to grow at the highest CAGR, during the forecast period. In Asian countries, the major source of electricity has been coal, which is why carbon dioxide emissions are alarmingly high here. Hence, the rising environmental awareness and rigorous guidelines intended at reducing GHG emissions will drive the adoption of waste heat recovery systems in the region.

In the Asia-Pacific region, the Indian market is the fastest growing. This is because India is home to a large number of energy-intensive industries, such as chemicals, manufacturing, steel, and petrochemicals, which generate a vast amount of waste energy during operations. With this rapid industrialization, the focus is moving toward adopting waste heat recovery systems to augment efficient energy use and enhance competitiveness.

Moreover, China is at the forefront of the adoption of this approach in APAC. In China, the adoption of these systems is due to its economic growth and expansion of many industries, such as food and beverage, chemicals, and cement. Essentially, the availability of low-cost raw material and labor has made it a manufacturing hub. Along with this, the cement industry is expanding in the country, thus driving the requirement for waste heat recovery systems in the cement industry.

Europe Is Largest Market for Waste Heat Recovery Systems

The largest market for waste heat recovery systems is Europe. The European Union's guidelines to generate electricity from waste and the increasing public awareness of energy efficiency and air pollution are the key market growth drivers in this region.

North America is also expected to witness significant growth in the market in the forecast period. As onsite electricity generation has increased and the regional economy has been majorly stable, there has been an increase in the demand for waste heat recovery in this region. Moreover, after China, the U.S. generates the highest amount of GHGs, which is why governments have implemented stringent environmental preservation guidelines.

Want a report tailored exactly to your business strategy?

Request CustomizationWant an insight-rich discussion with the report author?

Speak to AnalystOur dedication to providing the most-accurate market information has earned us verification by Dun & Bradstreet (D&B). We strive for quality checking of the highest level to enable data-driven decision making for you

Our insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

With 24/7 research support, we ensure that the wheels of your business never stop turning. Don’t let time stand in your way. Get all your queries answered with a simple phone call or email, as and when required

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws