Report Code: 11402 | Available Format: PDF | Pages: 146

UV Metallized Caps & Closures Market by Metallizing Material (Aluminum, Alloy), by Plastic Type (Polypropylene, ABS), by Application (Cosmetics, Fragrance, & Skincare; Food & Beverage), by Geography (U.S., Canada, France, Germany, Italy, U.K., Poland, China, India, Brazil, Mexico, Saudi Arabia, South Africa) - Global Market Size, Share, Development, Growth, and Demand Forecast, 2013-2023

- Report Code: 11402

- Available Format: PDF

- Pages: 146

- Report Description

- Table of Contents

- Market Segmentation

- Request Free Sample

UV Metallized Caps and Closures Market Overview

The global UV metallized caps and closures market is estimated to attain a size of $297.0 million in 2017 and is projected to witness a CAGR of 4.2% during 2018-2023. The market is driven by increasing demand from different industries including cosmetics, fragrance, skin care, and food and beverage.

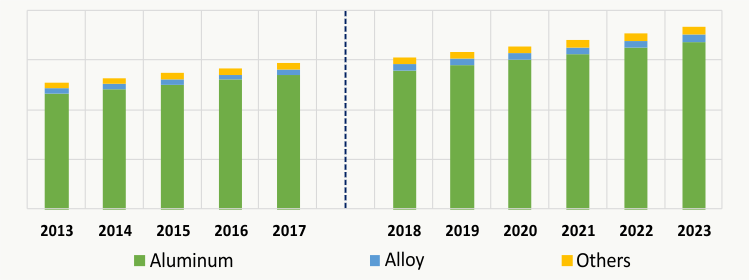

GLOBAL UV METALLIZED CAPS & CLOSURES MARKET, BY METALLIZING MATERIAL, MILLION UNITS (2013-2023)

Plastic caps and closures are used for the packaging of different cosmetics, fragrance, and skincare products such as lipsticks, perfume bottles, moisturizers, make-up kits, and others. The metallization of these plastic caps and closures is generally done through physical vapor deposition (PVD) sputtering. In order to protect the metallized layer and hide imperfections created on the surface of plastic caps and closures during the production process, ultraviolet (UV) curable coat is applied on them.

On the basis of metallizing material, the UV metallized caps and closures market is segmented into aluminum, alloy, and others. Others include chromium, silver, gold, and platinum. Aluminum has been the largest category in the market, with an estimated revenue contribution of more than 80.0% in 2017. Increase in the mining output of aluminum and stability of prices in commodity market are driving its application for the manufacturing of these caps and closures in the region.

Based on plastic type, the UV metallized caps and closures market is categorized into polypropylene, acrylonitrile butadiene styrene (ABS), and others. Others include polyvinyl chloride, polycarbonate, poly (methyl methacrylate) (PMMA), and polyethylene. Polypropylene has been the largest category in the market, with an estimated revenue contribution of more than 70.0% in 2017. This is attributed to its various benefits such as low cost, high flexural strength, chemical resistance against food and cosmetic ingredients, and high thermal resistance. Due to these benefits, the use of polypropylene as plastic packaging material is growing among manufacturers of caps and closures for cosmetics, fragrance, and skincare products.

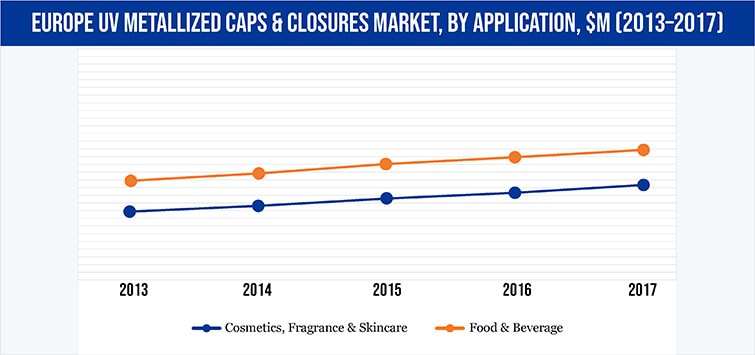

In terms of application, the UV metallized caps and closures market is segmented into cosmetics, fragrance, and skincare; and food and beverage categories. Cosmetics, fragrance, and skincare has been the largest category, with an estimated revenue contribution of more than 75.0% in 2017. The growing demand for metallized cosmetics components among consumers is driving the application of these caps and closures in the global market.

Globally, Europe has been accounting for the highest revenue in the UV metallized caps and closures market, with an estimated contribution of more than 35.0% in 2017. The low cost of metallizing materials and their compatibility with the PVD sputtering process are driving the market of these caps and closures in different countries across Europe.

UV Metallized Caps and Closures Market Dynamics

The major trends identified in the UV metallized caps and closures market are the rising use of vacuum metalizing technology, and growing reliance on UV based coatings for cosmetics caps and closures.

Trend

The rising demand of ultraviolet (UV) based curing technology for the coating of caps and closures for different applications, including cosmetic packaging, beverage packaging, and consumer goods packaging is identified as one of the key trends in the UV metallized caps and closures market. The method is employed for decorating different types of caps and closures with fine coating of aluminum or other alloys. The process involves the use of UV light instead of heat for the coating of different types of metals over caps and closures.

This process is highly productive over the traditional process of heat and air-drying method, which shrinks the initial application of coatings by 50%, and causes environmental pollution by releasing VOCs in the environment.

Drivers

The growing demand of metallized caps and closures in cosmetics industry, and rising demand of food and beverage are the two main driving forces of the global UV metallized caps and closures market. The improvement in the macroeconomic conditions of emerging economies has increased the disposable income of its population. The rising disposable income has led to an increase in the consumption of food and beverage products. As food and beverage is one of the major application areas of these caps and closures, the growth in the demand for these products over the years has positively impacted the growth of the UV metallized caps and closures market.

Also, there has been an increase in the consumption of alcohol in different countries. For example, Australia’s consumption of alcohol grew from 9.52 lt. per capita in 2014-2015 to 9.70 lt. per capita in 2015-2016, and is expected to reach 9.72 lt. per capita in 2018.

Restraints

The high cost of production of UV metallized caps and closures is the main restraint against the growth of the global UV metallized caps and closures market. The cost of production of these caps and closures is high as compared to the production of plastic caps and closures, which is denting its attractiveness among mass cosmetics brands. The cost of production also depends on various factors, such as volatility in prices of metal and cost of UV curing equipment. In addition, non-attainment of economies of scale due to low volume of output also increases the cost of production.

UV Metallized Caps & Closures Market Competitive Landscape

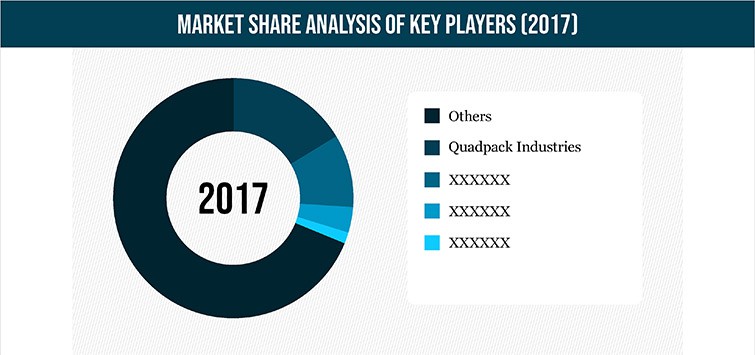

Some of the major players operating in the UV metallized caps and closures industry Albea Beauty Holdings S.A., RPC Group Plc, HCP Packaging Co. Ltd., Quadpack Industries, Eurovetrocap Spa, ILEOS, Essel Propack Limited, Politech Sp. z.o.o, Lumson S.p.A, and Hangzhou Zhenhua Daily Chemicals Glass Co. Ltd.

Want a report tailored exactly to your business strategy?

Request CustomizationWant an insight-rich discussion with the report author?

Speak to AnalystOur dedication to providing the most-accurate market information has earned us verification by Dun & Bradstreet (D&B). We strive for quality checking of the highest level to enable data-driven decision making for you

Our insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

With 24/7 research support, we ensure that the wheels of your business never stop turning. Don’t let time stand in your way. Get all your queries answered with a simple phone call or email, as and when required

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws