Report Code: 10940 | Available Format: Excel

Hydraulic Press Machine Market Forecast Report - Global Size, Share, Recent Trends, Strategic Developments, Segmentation Analysis, and Evolving Opportunities, 2024-2030

- Report Code: 10940

- Available Format: Excel

- Report Description

- Table of Contents

- Request Free Sample

Hydraulic Press Machine Market Size & Share

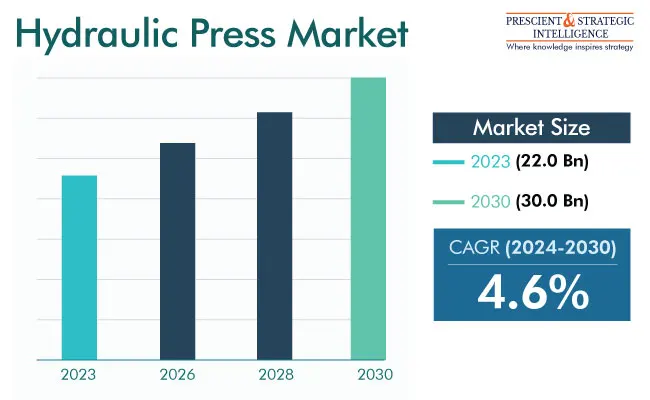

The hydraulic press machine market generated revenue of USD 22.0 Billion in 2023 (E), and it will advance at 4.6 % CAGR during 2024–2030, to reach USD 30.0 Billion by 2030.

This is because of the increasing automation & industry 4.0 acceptance; surging requirement for lightweight & high-strength materials; emphasis on sustainability & environmental concerns; and growing application.

A hydraulic press machine utilizes hydraulic pressure to squeeze or press materials such as metals to the desired shapes. It comprises a hydraulic cylinder, which applies force over a piston onto the material being processed. Hydraulic presses represent a category of machines that are highly adaptable and are used in metal forming, molding, and various manufacturing processes. They can shape, cut, and assemble metal parts with high accuracy and quality.

Hydraulic press machines are important as they help in the streamlining of processes in industries such as automotive and electrical & electronics. Through these machines, the mass production of highly intricate metal products is accomplished while maintaining uniformity and maximum quality.

Drivers

- Increasing automation & Industry 4.0 acceptance: Manufacturers are implementing automation technology to boost efficiency as well as productivity. The hydraulic press machines are incorporated with sensors, data analytics, and robotics, making them smarter and more automated.

- In April 2021, Bosch Rexroth presented the CytroForce hydraulic linear drive, a compact axis for movement, power, and aligning tasks in presses as well as machine tools.

- The plug-and-produce system, containing flow-optimized standard modules, sets new standards in terms of energy efficiency, quiet operation, and power density.

- Growing applications: Hydraulic press application goes beyond metalworking and automotive manufacturing. They are being used in sectors such as food & beverage and ceramics & abrasives.

- Surging need for lightweight & high-strength materials: Sectors such as electrical & electronics and automotive are progressively choosing aluminum, high-strength steel, and composite. Hydraulic presses have the advantage of forming and shaping such materials as a result of their precision and great force capacity.

- For instance, the global demand for automotive lightweight material will reach a value of USD 128,010.1 million in 2030.

- Emphasis on sustainability & environmental concerns: Companies are trying to switch production to environmentally friendly processes to lessen their ecological footprint. This has led to the development of energy-efficient hydraulic systems that have biodegradable fluids and less waste generation.

Trends

- Customization & specialization: Hydraulic press providers are now offering tailored hydraulic press solutions as per the different customer requirements and applications. This trend is fueled by the increasing need for specialized applications as well as complex procedures.

- For example, Macrodyne Technologies Inc. provides superior presses precisely intended to meet the requirements of BEV, PHEV, and EV automobile production.

- Incorporation of developed technologies: The implementation of technologies such as AI, ML, and IoT is driving the industry. These technologies allow remote monitoring, process optimization, and predictive maintenance, which ultimately lead to better performance and production uptime.

- Rising online sales & digitalization: The industry is moving towards sales via online channels as well as digital platforms. This trend is being fueled by the efficiency, transparency, and convenience provided by online platforms.

- For instance, 24/7 accessibility enables for purchases anytime, removing limitations of store hours.

- Emphasis on safety & ergonomics: The development of safety regulations and enhancement of the well-being of workers are the main factors behind innovative and safe designs of hydraulic press. These include functions such as better guarding, noise reduction measures, and automated shut-off systems.

- Complying with various safety regulations, such as ANSI B11.2 Hydraulic Press Safety Standard, CE, CSA Z142, and UL, is important.

Growing Need for Plastic and Fiber Materials Is Key Challenge

Globally, manufacturing sectors have become more dependent on plastic and fiber materials to substitute metals used in aerospace interiors and parts, electrical equipment, and car body parts because of their non-corrosive and lightweight attributes. In contrast to metals, plastics can be used more than once as, basically, their features generally do not change and they serve a greater lifespan than metals.

- For instance, the Boeing 787's fuselage is made up of around 50% carbon fiber reinforced plastic (CFRP).

Therefore, the use of plastic material is growing across different manufacturing industries, which in turn lowers the demand for metals. This may end up being a negative factor that would hinder the growth of the industry as hydraulic press machines are generally used for shaping, coining, or bending metal components. Hence, this problem is likely to cause a hurdle in the industry expansion during this decade.

| Report Attribute | Details |

Market Size in 2023 |

USD 22.0 Billion (E) |

Revenue Forecast in 2030 |

USD 30.0 Billion |

Growth Rate |

4.6% CAGR |

Historical Years |

2017-2023 |

Forecast Years |

2024-2030 |

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

Explore more about this report - Request free sample

Automotive Category Is Largest Contributor

The automotive category, based on industry, is the largest contributor to the industry. The widespread utilization of hydraulic press machines as a key tool in the automotive industry signifies their importance. The largest share of the category is because of the industry's dependence on fabricated metals, the efficiency provided by hydraulic press machines, and the low cost of labor associated with the use of these machines.

- The typical passenger vehicle comprises of around 65% iron and steel, by weight.

Therefore, the automotive category is a major factor responsible for the machine’s prevailing presence in the metal fabrication processes.

C-Frame is Significant Contributor

The C-frame category, based on type, accounts for a significant share of the industry. The growth of the category can be ascribed to their flexibility as well as an extensive range of applications. Such machines are characterized by a C-frame structure and are utilized for carrying out the processes of punching, forming, or bending in the automotive, manufacturing, and aerospace sectors. As the end-use sector looks for more accurate and flexible machines, the C-frame category will continuously play a major part in catering to these rising requirements, thus driving their acceptance.

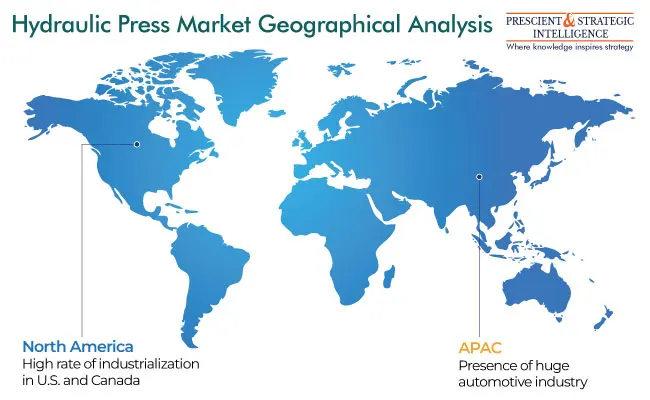

APAC Is Leading Market

Globally, APAC is the largest contributor to the industry. The development in the automotive, as well as general machinery area in the region, is likely to drive the adoption of hydraulic press machines. India, China, Japan, Thailand, Indonesia, and South Korea are the major nations assisting the expansion of the regional industry.

Moreover, the automotive industry is a major user of press machines in this region, with China standing as a major automaker in APAC. Furthermore, the forging sector is also another key user of hydraulic press machines in APAC, with China being the leader. Additionally, Japan and India are the other significant producers in APAC. As a result, these reasons are likely to boost the expansion of the regional industry in the years to come.

- In 2021, China produced over 21.4 million cars and 4.6 million commercial automobiles, totaling just over 26 million vehicles.

Competitive Landscape

The hydraulic press machine market is highly fragmented, with the existence of several regional as well as international companies, which also contributes to the competition among these companies.

- January 2022 – Macrodyne Technologies Inc., a major hydraulic press manufacturer in North America, acquired Dunkes GmbH, a key German press manufacturer with extensive knowledge in metal forming as well as industry-leading straightening & joining technologies.

Major Companies in the Industry

- Greenerd Press & Machine Company Inc.

- Andritz AG

- Beckwood Press Company

- Macrodyne Technologies Inc.

- Betenbender Manufacturing Inc.

- ASAI SANGYO CO. LTD.

- Dake Corp.

- Enerpac Tool Group Corp

- DORST Technologies GmbH & Co. KG

- Gasbarre Products Inc.

- Hefei Metalforming Intelligent Manufacturing Co. Ltd.

- JIER Machine-Tool Group Co. Ltd.

- Kojima Iron Works Co. Ltd.

- Jiangsu Yangli Group Co. Ltd

- Japan Automatic Machine Co. Ltd.

- Komatsu Ltd.

Want a report tailored exactly to your business strategy?

Request CustomizationWant an insight-rich discussion with the report author?

Speak to AnalystOur dedication to providing the most-accurate market information has earned us verification by Dun & Bradstreet (D&B). We strive for quality checking of the highest level to enable data-driven decision making for you

Our insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

With 24/7 research support, we ensure that the wheels of your business never stop turning. Don’t let time stand in your way. Get all your queries answered with a simple phone call or email, as and when required

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws