Report Code: 11450 | Available Format: PDF | Pages: 131

Alpha Olefins Market by Type (1-Butene, 1-Hexene, 1-Octene, 1-Decene, 1-Dodecene), by Application (Polyolefin Comonomers, Surfactants & Intermediates, Synthetic Lubricants, Petroleum Additives, Plasticizers, Oilfield Chemicals), by Geography (U.S., Canada, Germany, U.K., France, Italy, Russia, China, Japan, India, Singapore, Brazil, Mexico, Saudi Arabia, U.A.E., South Africa) - Global Market Size, Share, Development, Growth, and Demand Forecast, 2013-2023

- Report Code: 11450

- Available Format: PDF

- Pages: 131

- Report Description

- Table of Contents

- Market Segmentation

- Request Free Sample

Alpha Olefins Market Overview

The global alpha olefins market is estimated to attain a size of $11,704.2 million in 2017 and is projected to reach $15,846.5 million by 2023, witnessing a CAGR of 5.4% during 2018–2023. The market is mainly driven by the increasing application of the compound in the production of specialty chemicals and polyolefin comonomers.

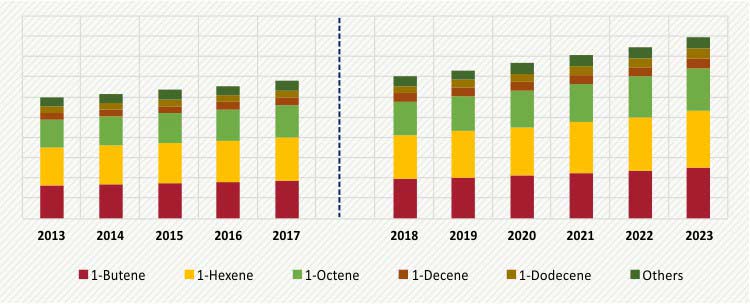

GLOBAL APHA OLEFINS MARKET, BY TYPE, KILOTONNES (2013–2023)

Alpha olefins are alkenes or olefins with chemical formula CxH2x. They are differentiated from other mono-olefins on the basis of linearity of the hydrocarbon chain, and the position of the double bond at the alpha position. A primary feedstock for the manufacturing of alpha olefin is ethylene, that is produced by using gas-based oil and naphtha.

On the basis of type, the alpha olefins market is segmented into 1-Butene, 1-Hexene, 1-Octene, 1-Decene, 1-Dodecene, and others. ‘Others’ include 1-Tetradecene, 1-Hexadecene, 1-Octadecene, and C20–C30 linear alpha olefins (LAOs). 1-Hexene has been the largest alpha olefin type in the market, with an estimated revenue contribution of more than 30.0% in 2017. This is attributed to its use in the production processes of various products, such as oxo alcohols, hexyl mercaptans, and synthetic fatty acids. It is majorly used in the production of polyethylene and polypropylene, which are the major building blocks of the petrochemical industry.

Based on application, the alpha olefins market is categorized into polyolefin comonomers, surfactants and intermediates, synthetic lubricants, petroleum additives, plasticizers, oilfield chemicals, and others (includes applications in the production of synthetic acids, property-enhancement of waxes, and in the production of paper-sizing chemical). Of these all, polyolefin comonomers is the fastest growing category in the market, expected to witness a CAGR of 5.6% during the forecast period, in terms of value. This is attributed to the increasing use of polyethylene, a type of polyolefin, in various industries such as plastic packaging, cables, and others.

Globally, North America has been accounting for the highest revenue in the alpha olefins market, with an estimated contribution of more than 50.0% in 2017. This is attributed to the high consumption of plastic in the region along with increasing production capacity of the compound, which is majorly driving the market growth, as the compound is the major raw material in the production of polyethylene, which is the most widely accepted plastic resin.

Alpha Olefins Market Dynamics

The major trend identified in the alpha olefins market is the growing demand for heavier alpha olefins (C6+) in North America and the Middle East.

Trend

The major trend witnessed in the global alpha olefins market in recent years is the growing demand of heavier olefins in North America and the Middle East.

North America is one of the largest producers as well as consumers of the compound. In the region, a number of ethylene cracker plants with integrated specialty grades polythene production facilities have become online, in recent years. 1-Octene based LLDPE offers greater resistance to external stress, lower density, and greater stiffness as compared to LLDPE. These properties make 1-Octene based LLDPE the first choice for lightweight but durable packaging materials for consumer goods and equipment manufacturing. Owing to such benefits, the preference for heavier LAO is emerging in the U.S. and other North American countries, driving the alpha olefins market growth.

Additionally, in the Middle East, the preference for heavier LAO based LLDPE in the automotive and consumer goods industries is growing, owing to the many benefits of the compound, as stated above.

Drivers

Rising demand for polyolefin comonomers and growing application of the compound in the production of specialty chemicals are identified as the major factors driving the growth of the alpha olefins market.

This compound is used as a raw material in the production of different specialty chemicals such as surfactants, oilfield chemicals, lubricants, plasticizers, plastomers, and others. For example, ethylene alpha-olefin copolymers are known as plastomers and are produced from the polymerization process. Plastomers exhibit hybrid properties of elastomers and plastics, and due to such properties, these materials are used in polymer modifications and packaging applications. Additionally, they offer good foaming, high compatibility with hard water, and low-cost benefits in surfactant production. Owing to these benefits, the demand for this compound is growing in surfactant production, which is driving the alpha olefins market growth.

Poly-alpha-olefin based lubricants offer greater oxidative stability and higher viscosity index as compared to mineral oils. Due to these benefits, the application of alpha olefin in lubricant production is growing.

Restraints

Increase in cost of operation as compared to the estimated budget for the production of the compound in plants, has become a worrisome concern for producers. This has been identified as the major restraining factor for the alpha olefins market.

The production of this compound requires massive infrastructure layout, raw material sourcing, logistic activities, downstream activities, and availability of storage facility. For vertically integrated producers such as Saudi Basic Industries Corporation and Royal Dutch Shell Plc, the smooth flow of production the monitoring of raw material movement, production processes, and others, in their ethylene cracker. The surpassing of production cost from the estimated budget occurs due to multiple reasons such as insufficient planning, inaccurate cost and time estimations, ineffective management, poor controls, contract ambiguity, poor productivity, cash constraints, lack of adequate skilled labor, and natural calamities. All these factors are hindering the alpha olefins market growth.

Alpha Olefins Market Competitive Landscape

Some of the major players operating in the global alpha olefins market are Royal Dutch Shell Plc., Chevron Phillips Chemical Company LLC, INEOS Group Holding S.A., Evonik Industries AG, Saudi Basic Industries Corporation, ExxonMobil Corporation, Qatar Chemical Company Ltd., PJSC Nizhnekamskneftekhim, Sasol Limited, and Idemitsu Kosan Co. Ltd.

Want a report tailored exactly to your business strategy?

Request CustomizationWant an insight-rich discussion with the report author?

Speak to AnalystOur dedication to providing the most-accurate market information has earned us verification by Dun & Bradstreet (D&B). We strive for quality checking of the highest level to enable data-driven decision making for you

Our insights into the minutest levels of the markets, including the latest trends and competitive landscape, give you all the answers you need to take your business to new heights

With 24/7 research support, we ensure that the wheels of your business never stop turning. Don’t let time stand in your way. Get all your queries answered with a simple phone call or email, as and when required

We take a cautious approach to protecting your personal and confidential information. Trust is the strongest bond that connects us and our clients, and trust we build by complying with all international and domestic data protection and privacy laws